Alice June Inc., a print studio based in St. Petersburg, Fla., found a creative way to bring local color (and local black-and-white) to City Place, a new residential complex in St. Petersburg. City Place wanted to highlight local landscapes and landmarks, so Alice June and the interior designer collaborated on a wall mural concept that would provide contrast for visibility while complementing the overall design and décor of the complex.

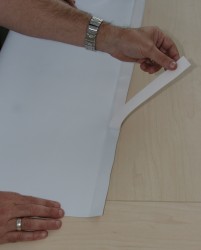

Installed in the lobby and the club room, the finished piece features LexJet Velvet WallPro SUV wallcovering in a three-foot high strip, printed in grayscale, offset with color images printed on vinyl, laminated with a matte finish, applied to black-edge Gatorboard and mounted with standoffs about a half inch from the wall.

Installed in the lobby and the club room, the finished piece features LexJet Velvet WallPro SUV wallcovering in a three-foot high strip, printed in grayscale, offset with color images printed on vinyl, laminated with a matte finish, applied to black-edge Gatorboard and mounted with standoffs about a half inch from the wall.

Alice June president, Sally Zimmermann, says the combination of color on the grayscale background, the difference in texture between the wallcovering and the vinyl images, as well as the classy and complementary look of the wallcovering with the paint scheme and finish created the exact look and feel the client was looking for.

“Because it’s a residential complex as opposed to a more commercial project, I feel like vinyl looks more commercial, so the Velvet WallPro was a great fit. They wanted something softer with a higher-end look, as well as something that would play off the color images so that you have an image and texture contrast,” says Zimmermann. “We did a similar project years ago for a commercial client, but in that case we did the opposite – we used a bright color background with the standoff images in grayscale. The opportunity to personalize a project so much and to work closely with the client to provide a creative solution that’s exactly what they need is what we really love to do.”

Zimmermann says that the quality of the original photos, shot by professional photographer Dirk Shadd, was “outstanding,” and that Shadd was a helpful partner in the process. “He made it easy for us to realize the vision and goal of our customer,” she adds.

Zimmermann says that the quality of the original photos, shot by professional photographer Dirk Shadd, was “outstanding,” and that Shadd was a helpful partner in the process. “He made it easy for us to realize the vision and goal of our customer,” she adds.