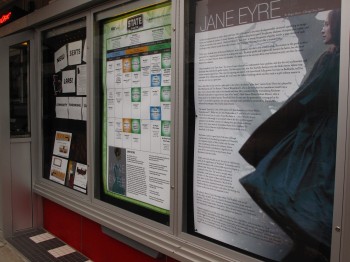

Globetrotting photographer and Renaissance man John Williams claims that Traverse City, Mich., is the “center of the known universe.” Be that as it may, Williams may very well have a point… to a point. Traverse City is one of the few bright spots of growth in Michigan, and the State Theatre that Williams bought and remodeled as a community-based, not-for-profit, volunteer-run movie theater is consistently among the top grossing theaters in North America.

Globetrotting photographer and Renaissance man John Williams claims that Traverse City, Mich., is the “center of the known universe.” Be that as it may, Williams may very well have a point… to a point. Traverse City is one of the few bright spots of growth in Michigan, and the State Theatre that Williams bought and remodeled as a community-based, not-for-profit, volunteer-run movie theater is consistently among the top grossing theaters in North America.

“We’ve already had over 500,000 patrons come through the doors since we opened in November 2007. The movie studios have taken notice, but they just can’t figure out how Traverse City on the back side of nowhere has this unbelievable theater doing unbelievable ticket business,” says Williams.

Perhaps it’s related to the incredibly successful Traverse City Film Festival that Williams helped launch in July of 2005. It also helps to have connections, like Williams’ long-time friend, film maker Michael Moore.

“For about a decade previous to starting the film festival, I had wanted to get one together and Michael is an obvious connection. He said, ‘Let’s do it in July,’ which was only eight weeks away, and we put it together. With his connections in Hollywood and my connections in town, we got it going and hung our hat on the motto, Just Great Movies. Now we’re one of the largest festivals in the U.S. in terms of paid attendance; we had over 110,000 people attend last year,” explains Williams.

Now the film festival board is filled with Hollywood luminaries and the film festival draws some of the brightest talent to showcase their work on what is at one time “the backside of nowhere” and the “center of the known universe.” This year, the film festival will be held July 26-31.

Williams also prints all the posters and signage for the event on his ancient Epson 10000. He’s had the printer since he first delved into inkjet and ditched the chemical process eight years or so ago. He has since added a Canon iPF8300 to the mix, but uses that for the bulk of his fine art and photography printing.

“I print a lot of the LexJet Sunset Photo Gloss Paper on the new Canon printer, and that stuff is magic on the printer. The gamut, range, saturation and sharpness on that paper are amazing. I also do a lot of fine art reproduction here and use the Sunset Textured Fine Art Paper or LexJet Premium Archival Matte Paper for most of those prints,” says Williams.

Though the Epson 10000 has plowed through more than 8 kilometers of paper over the years, and Williams has to plug it into an older Windows system since there are no compatible drivers for his latest operating system, it fits the bill for the rolls and rolls of LexJet TOUGHcoat Water-Resistant Polypropylene he prints for the event.

“It’s pretty simple; I just take care of my stuff,” says Williams about the printer’s longevity. “It’s been a real workhorse and shows no sign of quitting. For the film festival, we go through about 1,100 feet of the Water-Resistant Polypropylene just making the posters.”

To help with the artwork and workflow, Williams employs a bevy of college interns who vie for the opportunity to work on the film festival. “Some of them are graphic artists who funnel the art to me that gets printed here at the studio. They do all the trimming and mounting on foam board for the signs that aren’t going into windows,” adds Williams. “We buy cases of 40×60 foam board and keep laying them out on the board using spray mount, trim and apply them. We have a good system where you start at one end of the board, hold the material up high, and slowly put it down like a bed sheet. Doing it this way we never get bubbles in the material.”