HP recently announced two free training programs: HP Latex University and the HP Ecosolutions Trained Printing company program for HP Latex Printing Technology Users. The only “cost” is to register at either www.hp.com/ecosolutions/tpc or www.hp.com/go/hplatexuniversity (the links go to the same registration site, by the way).

HP recently announced two free training programs: HP Latex University and the HP Ecosolutions Trained Printing company program for HP Latex Printing Technology Users. The only “cost” is to register at either www.hp.com/ecosolutions/tpc or www.hp.com/go/hplatexuniversity (the links go to the same registration site, by the way).

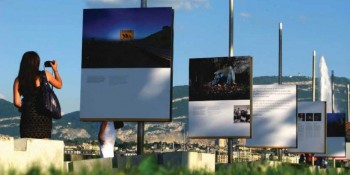

HP Ecosolutions: This training program includes nine modules across a range of sustainability topics and takes about two hours to complete. Themes include: “Go green” with your HP Latex printer, develop your organizations commitment to sustainability, and turn your new knowledge into new business. The program is designed to help you gain new knowledge and use new promotional tools to assist customers looking for wide-format graphics solutions with a reduced environmental impact.

HP Latex University: When you register at HP Capture via the HP Latex University link above, you will have access to workshops led by industry experts, online webinars and instructional guides to key HP Latex applications. Basically, it’s a set of training materials to help HP Latex users successfully produce a wide range of outdoor and indoor wide format graphics applications with HP Latex Printing Technologies.

If you have any questions, need help finding the right printer and materials for your business, or would like to know more about HP Latex Printing Technologies, contact a LexJet customer specialist at 800-453-9538. LexJet carries the HP Designjet L26500 61-inch Latex Printer and the HP Designjet L28500 104-inch Latex Printer.