Printing point of sale promotions and advertising can become a bit humdrum: banners, cooler wraps, window signs… They’ve all been done, but that’s the beauty of the plethora of the latest printer technology and printable materials; you can advertise on just about anything.

Printing point of sale promotions and advertising can become a bit humdrum: banners, cooler wraps, window signs… They’ve all been done, but that’s the beauty of the plethora of the latest printer technology and printable materials; you can advertise on just about anything.

At Caffey Distributing in Greensboro, N.C., production manager Bob Korabek has been finding new places to stick adhesive-backed materials to boost their brands at the point of sale, like cornhole boards for tournaments and on mini-fridges.

Cornhole, in case you’re not familiar with it, is a bean bag toss game that has swept through bars and pubs across the nation. Rumor has it that the game, at least the version now being played, was popularized in Cincinnati, moving its way south as transplanted Ohioans moved to warmer climates.

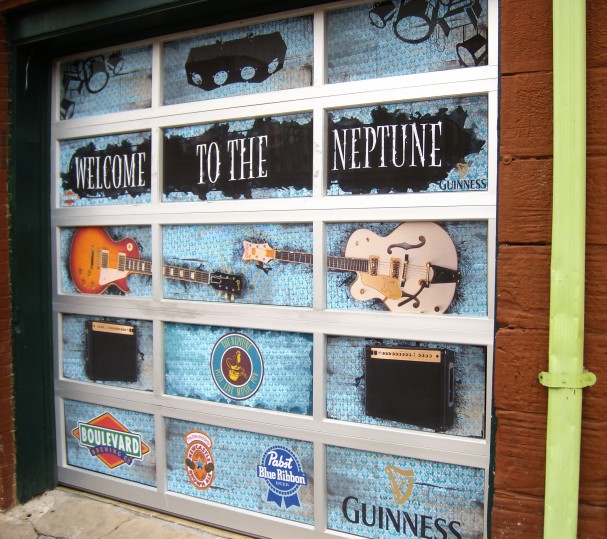

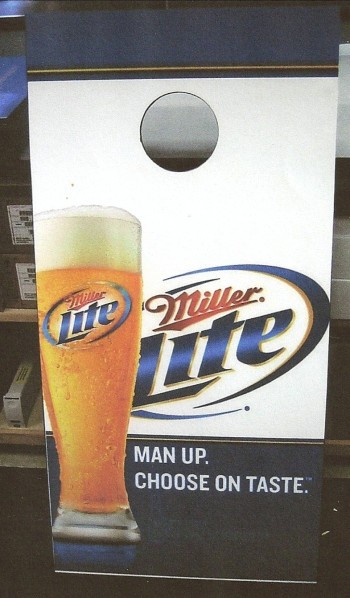

Whatever its origin, Korabek saw promotional opportunity and ran with it as local bars began holding cornhole tournaments. It’s a simple process: Korabek prints LexJet Extreme AquaVinyl w/ PSA on one of his HP Z6100 inkjet printers, applies it to the approximately 4′ x 2′ board and cuts out the vinyl where the hole at the top of the board is located.

“The bars set up four sets of boards for the tournaments, and the winners get some kind of big prize. I printed some with Miller Lite, Blue Moon and other beers we wanted to promote, usually tied in with a beer special,” explains Korabek. “Instead of just a logo in the middle of the board, I covered the entire board to give us more promotional space.”

The printed cornhole boards have been a huge hit in the market, creating widespread interest and driving demand for both the game and the printed versions of the game.

The printed cornhole boards have been a huge hit in the market, creating widespread interest and driving demand for both the game and the printed versions of the game.

Another popular application for adhesive-backed materials that Korabek introduced to the market is decorated mini-fridges. The graphics are usually tied to whichever sport is in season, whether it’s football or basketball.

Because the temperature of the mini-fridges can vary, Korabek was looking for a material that wouldn’t expand and contract as the fridge got colder or warmer. His customer specialist, Kelly Price, recommended LexJet TOUGHcoat Water-Resistant Self Adhesive Polypropylene.

“They’re very popular and our accounts will often buy a couple of extra ones. For one of the March Madness promotions the contest winner got a fridge with the team they wanted on the fridge. It’s a little perk that our competitors don’t provide; it’s something extra special we do for those accounts,” says Korabek.

“When I first started here 16 years ago all I had was a Gerber EDGE and a plotter. The technology has moved so quickly since then and Kelly is awesome because she keeps me up to date on new products and she gives me great suggestions that work for my printers and any application I’m trying,” adds Korabek. “Plus, with LexJet’s distribution network I get everything on time; turnaround time for me is super-fast.”