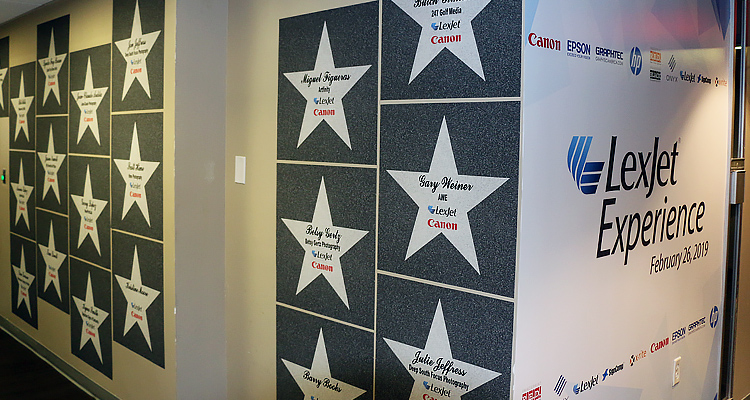

The LexJet Experience was a success! Our open-house showcased equipment, RIP software and media applications for local customers. Representatives were on hand from Canon, EPSON and HP as well as GRAPHTEC, SignComp framing systems, Onyx and ImagePrint.

Set up on the third floor of the Sarasota, Fla. headquarters, the trade show-style event allowed LexJet customers the opportunity to discuss current technology, best practices and innovative applications with the vendors of their choice.

Set up on the third floor of the Sarasota, Fla. headquarters, the trade show-style event allowed LexJet customers the opportunity to discuss current technology, best practices and innovative applications with the vendors of their choice.

Vince Bejar, LexJet sales representative, had several customers in attendance. “They were excited about the opportunity to visit our office,” he says. “They enjoyed the hospitality and are looking forward to growing with our partnership.”

Timothy Mitchell, the resident expert in all things HP Latex, was available to discuss the best media to use with the latex printers, including his recent review of the new HP Prime Gloss Air GP.

With such an intimate setting, customers spent as much time as they needed with vendors. “I was happy about the way the customers engaged in conversations with everyone,” said HP Partner Business Manager, Frank DeMartino. “They had questions about specific applications for both the latex printers and the Z-series printers, and they wanted to learn more about the vertical trimmer on the Z9+.”

Craig Hellman, Senior Account Manager for Epson, agreed that customers were seeking solutions for unique applications. “There was a lot of interest in dye-sub printing,” Hellman said. “They want to know how to create promotional products, displays, signage and, of course, apparel.”

Craig Hellman, Senior Account Manager for Epson, agreed that customers were seeking solutions for unique applications. “There was a lot of interest in dye-sub printing,” Hellman said. “They want to know how to create promotional products, displays, signage and, of course, apparel.”

With Epson’s breadth of products, it wasn’t just the dye-sub applications that piqued their curiosity. “People are very interested in what the SureColor S-Series (solvent) printers can do. They asked about signage and display, but they also want to know about décor printing.”

As the day began winding down, everyone seemed to have the same question: “When are you going to do this again? This was a great learning experience.”

As the day began winding down, everyone seemed to have the same question: “When are you going to do this again? This was a great learning experience.”

Given the positive feedback we’ve received, we look forward to doing another open house later this year. If you were in attendance, we’d love to hear from you. Please contact your LexJet sales representative at 800-453-9538, leave us a comment here on the blog, or visit our Facebook page.