Bellevue Fine Art Reproduction got its start as a way to solve a problem. For the company’s owner, Scott Moore, the problem was finding a way to reproduce his watercolor and pen-and-ink fine art. The solution was to do it himself, perfect the process and provide the service to artists and photographers in the Seattle/Bellevue area of Washington.

“At the time I was traveling a lot internationally and I tried places that did giclee printing in Japan, China, Canada and Paris. I wasn’t getting the color I wanted, and with the pen-and-ink I wasn’t getting the extreme detail I needed. Using my own artwork as a beta test I ended up making my own reproductions, and the more I looked around the more I saw that the Seattle area needed a business like this. There was a need for it, and there still is,” says Moore.

“At the time I was traveling a lot internationally and I tried places that did giclee printing in Japan, China, Canada and Paris. I wasn’t getting the color I wanted, and with the pen-and-ink I wasn’t getting the extreme detail I needed. Using my own artwork as a beta test I ended up making my own reproductions, and the more I looked around the more I saw that the Seattle area needed a business like this. There was a need for it, and there still is,” says Moore.

Moore opened the doors of Bellevue Fine Art Reproduction in April 2007, starting with a BetterLight scan-back system to scan and capture artwork, two Epson Stylus Pro 9800s and a software RIP for processing the files for print.

Since that time, Moore has updated his BetterLight System, upgraded to two Epson Stylus Pro 9900s, moved his RIP workflow to ImagePrint and most recently added a 24″ x 36″ laser engraver table. Moore says that about 90 percent of his business is fine-art reproduction; the other 10 percent is photo reproduction.

Since that time, Moore has updated his BetterLight System, upgraded to two Epson Stylus Pro 9900s, moved his RIP workflow to ImagePrint and most recently added a 24″ x 36″ laser engraver table. Moore says that about 90 percent of his business is fine-art reproduction; the other 10 percent is photo reproduction.

Moore serves a narrow niche, but is expanding the options and opportunities of his client base. Moore sees himself as far more than simply an art reproduction company; his job is to help his clients find a wider market for their work.

“We look at each artist’s artwork as intellectual property that can be productized in different ways, from limited edition prints to cutting vector designs of their work into various materials,” explains Moore. “We want to take people’s existing assets and help them do interesting things with them.”

“We look at each artist’s artwork as intellectual property that can be productized in different ways, from limited edition prints to cutting vector designs of their work into various materials,” explains Moore. “We want to take people’s existing assets and help them do interesting things with them.”

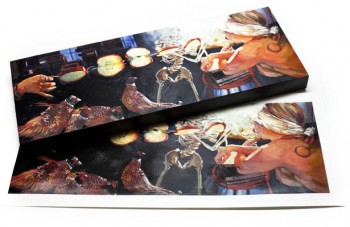

What that has translated to with the addition of the laser engraver is products like etching artwork into leather for purses, cutting patterns into Masonite that the artist then paints and has Bellevue Fine Art reproduce, die-cutting Photo Tex Repositionable Fabric for walls and other surfaces, and even etching urns for a local funeral home.

The addition of the laser engraver is a perfect fit for Moore’s customer service philosophy. As he puts it: “Providing good service is more than calling back and being on the ball. We’re very well connected with the art community so we provide a lot of services to people you wouldn’t normally think of, like gallery introductions, suggestions on where to show their work, and advice on ways to display and sell their work. Service is a lot more than giving someone a cup of coffee while they wait for their print. We try to be connected and active in the art world so we can complement our services in other ways, such as introductions and industry knowledge. It’s symbiotic; the more we do for them to help them be successful the more they come back to us because they are successful. Service is all about that ecosystem around the artist; anything I can do to help them be successful makes me more successful.”

The addition of the laser engraver is a perfect fit for Moore’s customer service philosophy. As he puts it: “Providing good service is more than calling back and being on the ball. We’re very well connected with the art community so we provide a lot of services to people you wouldn’t normally think of, like gallery introductions, suggestions on where to show their work, and advice on ways to display and sell their work. Service is a lot more than giving someone a cup of coffee while they wait for their print. We try to be connected and active in the art world so we can complement our services in other ways, such as introductions and industry knowledge. It’s symbiotic; the more we do for them to help them be successful the more they come back to us because they are successful. Service is all about that ecosystem around the artist; anything I can do to help them be successful makes me more successful.”

Of course it’s all for naught if Moore isn’t producing the output to the exacting needs of his client base, which is why he keeps up with the latest workflow and printing technology and spends additional time educating his clients and setting expectations.

“When we evolved to the Epson 9900s we also went with the ImagePrint RIP. If you’re in the business of printing art all day long, you don’t want to think about how to get it out the other end. When you drag and drop those images into the interface and select the correct profile, that’s all you have to think about. It makes our workflow that much faster; anyone who values their time should be willing to spend their money on that,” explains Moore. “Printing is just like painting. One of the successful traits of painter is knowing when you’re done. You could re-do it forever, but you’ll probably be the only one to notice. When you’re trying to reproduce a masterpiece for sale you have to strike a balance. We’re working with aqueous inks, where the originals are sometimes made with ground gems or minerals, creating iridescents, fluorescents and metallics. The challenge is helping them understand the limitations of the technology and how to best utilize it. Some people don’t want the reproduction unless it’s perfect. The prints are as close as we can get them, but if it’s that important, buy the original, which is why an original costs so much more. There’s only one perfect copy of an original, and that’s the original. We spend a lot of time setting expectations, and we won’t just write an order and take their money unless we think they will be happy with it.”

“When we evolved to the Epson 9900s we also went with the ImagePrint RIP. If you’re in the business of printing art all day long, you don’t want to think about how to get it out the other end. When you drag and drop those images into the interface and select the correct profile, that’s all you have to think about. It makes our workflow that much faster; anyone who values their time should be willing to spend their money on that,” explains Moore. “Printing is just like painting. One of the successful traits of painter is knowing when you’re done. You could re-do it forever, but you’ll probably be the only one to notice. When you’re trying to reproduce a masterpiece for sale you have to strike a balance. We’re working with aqueous inks, where the originals are sometimes made with ground gems or minerals, creating iridescents, fluorescents and metallics. The challenge is helping them understand the limitations of the technology and how to best utilize it. Some people don’t want the reproduction unless it’s perfect. The prints are as close as we can get them, but if it’s that important, buy the original, which is why an original costs so much more. There’s only one perfect copy of an original, and that’s the original. We spend a lot of time setting expectations, and we won’t just write an order and take their money unless we think they will be happy with it.”

Toward that end, Moore employs a variety of inkjet materials from LexJet, including Sunset and Hahnemuhle brand fine art and photo papers. Moore says the material choice is usually based on what comes closest to replicating the original. For instance, he’ll typically use Sunset Textured Fine Art Paper for watercolor art, Hahnemuhle Bamboo for “warmer” originals, and FineArt Baryta for acrylic originals.

“My personal favorites are Sunset Fibre Elite, Sunset Photo eSatin Paper, LexJet Premium Archival Matte and Hahnemuhle FineArt papers. Sunset Fibre Elite for black-and-white printing is stellar; it looks and feels a lot like the old metal halide papers. It’s a special, unique paper that, when placed next to other photo papers, really stands out; the color jumps out at you,” says Moore. “Our staple papers are Sunset Photo eSatin and Premium Archival Matte, which we use for proofing as well.”

Though Bellevue Fine Art Reproduction has only been in business for about five years, the company is attracting and retaining business beyond its borders, especially from those looking for high-quality scanning services.

Though Bellevue Fine Art Reproduction has only been in business for about five years, the company is attracting and retaining business beyond its borders, especially from those looking for high-quality scanning services.

“We’ve invested heavily in making sure our image scanning and output is the best it can be. We pick quality materials and equipment, and we don’t worry about cost that much. How we do that and compete in today’s world is that we’ve captured a niche that is high margin and low volume. We’ll take the jobs other printers don’t want; we’ll do 10 watercolors, for instance, that a commercial print company would prefer not to bother with,” says Moore. “So rather than compete with larger print shops, we actually complement them. There are a number of print shops in the area that come to us for scanning, and they do things we don’t do, so we have a good complementary business with our would-be competition in the area.”