During the great digital color output revolution of the mid-90s, a host of traditional reprographic and pro photo lab companies died on the vine. The transition was difficult for any number of reasons, but much of it having to do with the question of when to write off the large capital expenses of the previous tried and true technology in favor of a less expensive but immature technology. It was not only a question of adopting new technology, but exploring and adopting new markets and clientele.

During the great digital color output revolution of the mid-90s, a host of traditional reprographic and pro photo lab companies died on the vine. The transition was difficult for any number of reasons, but much of it having to do with the question of when to write off the large capital expenses of the previous tried and true technology in favor of a less expensive but immature technology. It was not only a question of adopting new technology, but exploring and adopting new markets and clientele.

Keith Fabry Reprographic Solutions, which had been providing traditional blueprints since 1958, succeeded in that transition and thrived. Keith Fabry, based in Richmond, Va., not only transitioned, but held onto its core business. The company was able to expand its large-format digital graphics offerings while maintaining a steady reprographics business, emerging stronger and more capable overall.

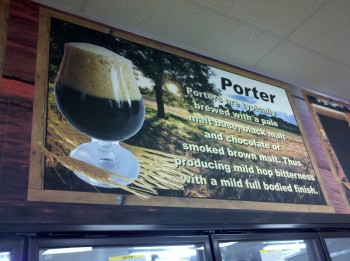

“In the late ‘90s we got an Epson printer from LexJet and a solvent printer and started doing banners and high-end posters. Then we got a flatbed printer [an Oce 550 GT with white ink and roll-to-roll] and are now doing aqueous, solvent and UV-curable printing, plus we have CNC routing equipment, three laminators, fabricating equipment with a small wood shop and full-time designers and installers on staff,” says operations manager Ricky Shannon. “It’s difficult to categorize what is essentially a modern sign shop, but we still do a lot of architectural printing, like building documents and presentation boards for architects. A separate building handles blueprinting and commercial printing, while here at this building we do large-format printing. Whether we’re doing museum or retail work, fine art and photography reproduction, special events, trade shows or displays for new home developments, every day is a different experience.”

Keith Fabry recently updated its aqueous inkjet printing capabilities with a 44” Canon iPF8300 from LexJet and does most of its fine art and photographic reproduction with the printer. Generally, the UV-curable flatbed printer is used mainly for rigid substrates and the solvent printer for outdoor projects.

“It depends on the final application: What they’re using it for, how much sunlight and temperature the project will take, and whether the material needs to be conformable, especially with UV-curable since the inks are too brittle to make curves, tight bends and stretch with the media. For higher image quality indoors we usually print aqueous. It’s a more lucrative area because the requirement is for higher-quality images on premium papers as opposed to high volume work,” explains Shannon.

Shannon says his favorite inkjet materials for high-end work are LexJet Sunset Photo eSatin, Sunset Photo Metallic and Sunset Fibre Gloss. “My favorite is probably the Fibre Gloss. It’s a good all-around paper, and I like the fact that there’s the slightest texture that shows through. I also like the Photo Metallic. I wouldn’t call it gimmicky, but if you’re looking for something non-traditional with a lot of pop, it’s a great choice,” says Shannon. “We print the Photo eSatin more than any other aqueous material. We find higher end photographers and artists that are re-selling their artwork prefer these nicer papers. For some of those projects we work through local frame shops where they’re packaging the artwork and contracting us to print it.”

Shannon adds the Keith Fabry prints for a client base that ranges from local college students to national franchise accounts, but it’s much more than simply printing. With its design and fabrication capabilities, Keith Fabry can take on practically any advertising or promotional project and is not afraid to do so.

“Our willingness to try new things and constantly expand our offerings – basically our lack of saying no – can get us into trouble, but it’s helped us grow a lot. We have clients who come to us because they know we can find a way to make their ideas happen,” says Shannon.