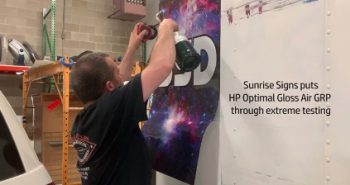

Recently, Scott Kaiser and his installation team at Sunrise Signs in Gloucester City, N.J., received a roll of HP Optimal Gloss Air GRP from LexJet. Before using any new product for a project, Kaiser says they like to push the material to the extreme. “Any time we try out new material, we torture it to see what it’s going to do,” he says.

So how did the Optimal fare? “We tortured it and it stood up great,” Kaiser says. “We stretched it and it didn’t white out, which can sometimes be an issue with latex inks. I also like the repositionable quality, and it really does take to those rivets!”

In the video above, you can see the intense testing of the Optimal laminated with HP Gloss Polymeric Overlaminate which includes stretching, overstretching, heating, rolling over rivets and repeated repositioning. Not only is an installer looking to see how well the color sits on the material, but checking performance on different surfaces is also important.

“We put it on some rough surfaces on that truck. It’s an old, beat up box truck and it was in terrible shape,” Kaiser says. “We wanted to see how it does when problem areas arise. We lifted it back up and reheated it to see if it went back to its shape. It did.”

When it comes to fleet or box truck graphic installations, there can be some challenges. “He (the installer) was putting some graphics on a super smooth trailer, and he liked working with it, but for another trailer, there were lots of rivets.”

Although there were many rivets on one of the jobs, Kaiser says the vinyl held tight. “They just had to work a little bit slower through those areas, but the vinyl held, and the rivets look tight.”

Kaiser says that he will continue to use the HP Optimal Gloss Air GRP protected with HP Gloss Polymeric Overlaminate for trailers and box trucks. “I’ve used other well-known brands before, and I think the HP Optimal had great success when compared to the other products,” he says. “Our installer even put it on his own trailer.”

Whether testing against the rigors of installing on a less-than-perfect surface or overstretching it to look for white-out conditions, Kaiser and his installer put the Optimal Gloss Air GRP through its paces, and both have declared it a “winner.”

If you are interested in learning more about the performance of the Optimal Gloss Air GP – or any other products in the HP Adhesive Vinyl line – call a LexJet specialist at 800-453-9538 or visit LexJet.com today.