What’s the point of advertising? The point is obvious, particularly if you’re trying to sell beer at various locations around town where the final sale is most often made at the point of sale. That’s a lot of points and no one makes those points better for beer than Tennyson Lacasio of Colonial Wholesale Beverage in North Dartmouth, Mass.

What’s the point of advertising? The point is obvious, particularly if you’re trying to sell beer at various locations around town where the final sale is most often made at the point of sale. That’s a lot of points and no one makes those points better for beer than Tennyson Lacasio of Colonial Wholesale Beverage in North Dartmouth, Mass.

Lacasio’s attention to design detail and the flawless production and installation of the signs that promote the various brands Colonial sells ensures that their brands get front-and-center attention at the liquor stores, convenience stores, bars, restaurants and other purveyors of suds that dot the landscape.

Eye-catching signage not only attracts customers in the store, but prompts owners and managers to request more signs and provide Colonial with more space with which to advertise in their establishments. Take two recent projects Lacasio put together for a couple of local liquor stores…

The first was a sign project located 15-20 feet above the store’s floor displays. The request was for three billboard-style 5′ x 11′ signs to be mounted to a wooden frame system above the floor displays. The three brands Lacasio was tasked with promoting were Coors Light, Miller Lite and Blue Moon.

The first was a sign project located 15-20 feet above the store’s floor displays. The request was for three billboard-style 5′ x 11′ signs to be mounted to a wooden frame system above the floor displays. The three brands Lacasio was tasked with promoting were Coors Light, Miller Lite and Blue Moon.

Given the visibility of the signs and the opportunity to outshine the competitors, Lacasio worked with the general concepts of each brand, but put his own brand on it by mixing and matching elements. For instance, on the Blue Moon sign Lacasio explains, “I was given a lot more liberty with the Blue Moon sign. Blue Moon has a fine-art style they use on some of their promotions, but the customer didn’t want to go that route. They felt the idea of the orange with the Blue Moon label wouldn’t go away, so they wanted to incorporate that element. What came out of it are blues, oranges and greens that are very bright and vibrant, making it stand out more than any of the other signs. The store manager was quite pleased with the result.”

Lacasio shifted elements, worked with complementary, brand-focused colors and a variety of bottle and can configurations on the other signs to accomplish his objective, which was to “make them very visible and readable from that distance without overdoing it.” Mission accomplished.

Lacasio shifted elements, worked with complementary, brand-focused colors and a variety of bottle and can configurations on the other signs to accomplish his objective, which was to “make them very visible and readable from that distance without overdoing it.” Mission accomplished.

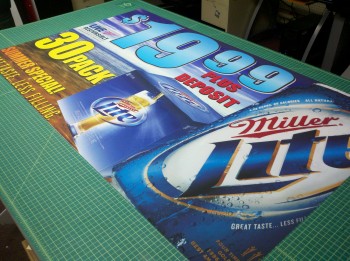

The graphics were applied to Duraboard using Photo Tex adhesive-backed fabric. To avoid unsightly screws in the graphics, which mar the adjacent competing signs, the Duraboard was first attached to the wood frame then the Photo Tex was applied for a smooth, seamless look. Bottom line? “They’ve been putting more of our products on the floor, so in that respect it’s had the desired effect. And, because of the signs we created, they’re putting in an additional three signs, and we’ll get two of those three spaces for our brands. We’ll get additional signage because they’re pleased with what we did. We were able to convey the product better than our competitors.”

The second project was for a seaside liquor store near the wharf with window signs and a long indoor wall wrap on tap. Again, Lacasio skillfully matched the necessities of branding with local color. In this case, he pulled beach, seagull and sailing themes to tie into the area, as well as a potent mix of colors to grab the attention of people passing by, driving by and walking out of the grocery store across the street.

The brands in this case were Miller High Life, Miller Lite, Coors Lite and Icehouse. For the Coors Light outdoor window sign as an example, Lacasio says, “The owner wanted to emphasize the cans in the sign so I used the Coors train, re-designed the background, added three cans in the image and put large impact red price points. The gold color in the writing actually pops off the Coors Light signs, more than the usual gray. It’s easy to read, getting across the product and the price while giving it enough composition on the bottom to accommodate the pricing on the top.”

The brands in this case were Miller High Life, Miller Lite, Coors Lite and Icehouse. For the Coors Light outdoor window sign as an example, Lacasio says, “The owner wanted to emphasize the cans in the sign so I used the Coors train, re-designed the background, added three cans in the image and put large impact red price points. The gold color in the writing actually pops off the Coors Light signs, more than the usual gray. It’s easy to read, getting across the product and the price while giving it enough composition on the bottom to accommodate the pricing on the top.”

Lacasio followed the same line of thinking for the rest of the outdoor window signs, combining colors and images for a cohesive whole that gets the message across effectively for each brand.

On the inside of the store, Lacasio created a 40-foot-long Coors Light banner with a beach, boat and bird theme. As Lacasio puts it, “I wanted something beachy, but not cheesy.” The indoor Coors Light banner was applied to the wall with LexJet TOUGHcoat Water-Resistant Self Adhesive Polypropylene, which was also used for the window signs, but applied to Coroplast that was then attached to the windows with  industrial-strength hook-and-loop fasteners (which you may know better as a trademarked name that starts with V and rhymes with Melcro).

industrial-strength hook-and-loop fasteners (which you may know better as a trademarked name that starts with V and rhymes with Melcro).

Lacasio adds, “The other signs were pretty poor at best and duct taped in the windows, so this gives us an opportunity to get more representation on the building itself. The quality of the signs outside allowed us to firm up the advertising space on the inside.”