The next-generation Sunset Gloss Coating and Sunset Satin Coating are now in stock and shipping from LexJet’s Nationwide Delivery Network. The popular coatings have been reformulated to improve canvas coating performance with consistent results that can be applied with a brush, roller or spray.

Sunset Gloss Coating and Sunset Satin Coating are non-yellowing, pH-neutral water-based acrylic coatings that are self-leveling and ready-to-use straight from the easy-to-pour, easy-to-store containers.

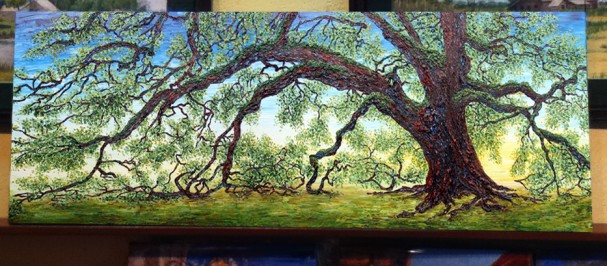

Randy Orgeron of Color Simulation Service, Thibodaux, La., provided detailed feedback when he tested the updated formulation of Sunset Gloss Coating on Sunset Select Matte Canvas. Among his findings, Orgeron noted:

- It rolls on easily with a foam roller

- There do not seem to be any issues with it gunking up and it lays flat from the offset

- Initially, the coating turns hazy, like car wax prior to buffing, but becomes crisp and clear

- There were some bubbles that formed during application; however, once completely dry that concern proved to be unwarranted

- The finish is gorgeous and really articulates the print, and there were no issues with the coating lifting the ink off the canvas

“The piece I tried this on at first was only an 11×14 canvas. Since the coating tends to set up rather quickly I was interested to see how fast I would have to work to cover a large canvas, and if could go back over missed spots on the first application,” adds Orgeron. “I’ve used other brands that dry so quickly you can only use them on smaller prints. With the Sunset Coating I found that you can keep working it after you apply it, so it’s going to be very effective for all of our prints, large or small.”

Other improvements to Sunset Coatings include:

- Greater UV protection

- Increase solid content so you get more coverage out of one container

- NMP-free to comply with state and local safety and health regulations

Call a LexJet print specialist today at 800-453-9538 to find out more and to order the new Sunset Coatings.