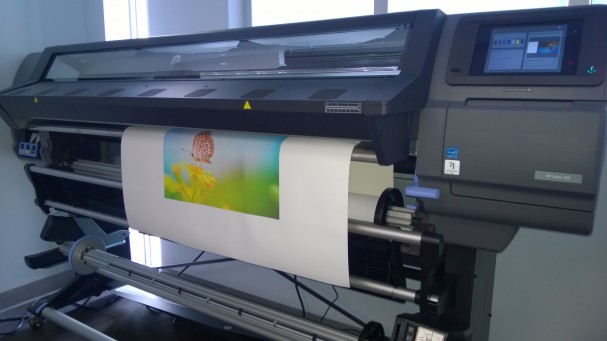

Is the new HP Latex 360 Printer all it’s cracked up to be? To find out, we asked LexJet’s technical support director, Adam Hannig, who has been working with the printer daily since it arrived at LexJet’s tech center a few weeks ago.

First, the 64-inch printer is meeting all the targets for quality, durability and production with high quality at high speeds, lower maintenance and a healthier printing environment. HP has also partnered with Graphtec and Summa for a true print-and-cut option. Click here to read more about how it works.

One of the features unique to the HP Latex 360 is HP Custom Substrate Profiling with an i1 embedded spectrophotometer. Hannig says this feature makes it simple to profile substrates, so simple that even if you have no knowledge about profiling, you can make it happen. Moreover, with onboard profiling RIP times are quite a bit faster.

“You lose some of the control you have to really get in deep and tweak a substrate profile, but this method is so much faster. There’s not another printer in the latex/solvent market that can do this,” says Hannig. “The other amazing thing is that it’s not RIP-specific so you can create a profile and it doesn’t matter what RIP you use. When you build a profile on the printer it automatically syncs with your RIP; it’s already built and ready to go.”

Another big time-saver, says Hannig, is the new maintenance cartridge system, which allows users to simply replace a cartridge instead of using a maintenance tank. “Now you only have to replace inks, printheads and the maintenance cartridge, so you’re down to the very simplest of options when it comes to regular maintenance of the printer,” says Hannig.

Hannig reports that start-up time – getting the printer “warmed-up” and ready to roll – is significantly lower with the new printer at only about a minute and a half. “If you do a lot of stop-and-start printing where you print a job and then another job half an hour later, the new system cuts down on the time it takes for it to get ready. It has something called a Latex Optimizer, which holds the ink in place until it gets to the heater for instant-dry printing,” says Hannig.

Another new feature on the printer is the LCD touch screen, but Hannig says that while it’s nice to have and includes a preview of the job that’s currently printing, he’s most impressed with the intuitive menu and the internet connectivity.

“If you go to the Substrate Library menu on the printer you can download profiles and it will install them right there. You don’t have to go to your computer; you do it right from the printer, which accesses HP’s Media Finder,” says Hannig.

Hannig adds that he’s impressed with the image quality and the apparent added durability of the next-generation HP Latex Inks.

“For canvas production, as well as other graphics where you’d like to cut out the coating or lamination step, the increased durability is very important. HP developed a different type of polymer around the ink that makes it more durable. You want that peace of mind when you ship it and your customer puts it up on the wall.”

Stay tuned for a series of videos that detail how to use the new HP Latex Printers.