Lou Fiore, owner of Speedway Custom Photo Lab in Daytona Beach, Fla., has been kind enough to share some great ideas, which we’ve posted here at the LexJet Blog (LED Backlit Conference Room Graphics and Creating a Multi-Panel Display).

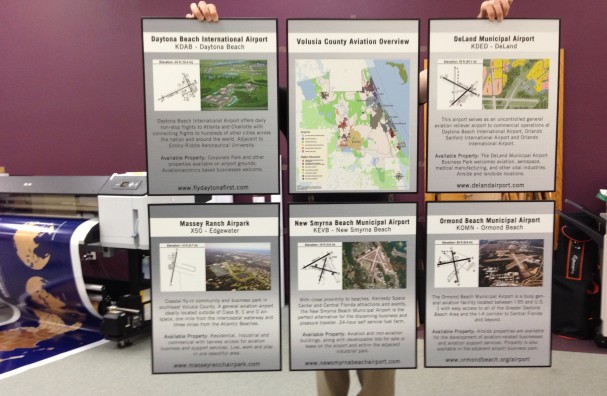

To round out the trio of ideas, Fiore shares his process for making perfectly flat banners for banner stand displays, what he calls the “Holy Grail” of banner stands.

To round out the trio of ideas, Fiore shares his process for making perfectly flat banners for banner stand displays, what he calls the “Holy Grail” of banner stands.

“Regardless of how lay-flat manufacturers say a certain banner material is, you usually get some curl, and it varies depending on the material,” says Fiore. “Recently, I tried LexJet TOUGHcoat Water-Resistant Polypropylene with GBC 5 Mil Octiva Low-Melt Emboss 50 Laminate. While at first glance, you wouldn’t think this is a good match since the laminate is applied at temperature, but the result is astounding, with absolutely knife-sharp flat edges.”

Fiore’s technique is to print the Water-Resistant Polypropylene on his Epson 9800, then the GBC Emboss 50 is applied using a sled at the lower end of its low-melt temperature range, around 170 degrees F. The laminate is allowed to cure for about an hour and the banners are then trimmed on a Keencut Sabre 2 General Purpose Cutter (120 in.).

“Initially, the edges appear to have some curl, but once the protective layer is peeled off of the Emboss 50, the banner lays absolutely flat and stays flat when it’s under the spring tension of the banner stand,” explains Fiore. “One nice characteristic of the Emboss 50 is that it’s a 5-mil vinyl, which is very flexible and not bulky. Plus, it has a very light crystal surface that doesn’t kill the pop of the print, yet it kills the reflection off of the graphic. I show this to my customers so they can see how beautiful the laminate is; that’s how much I like it.”

“Initially, the edges appear to have some curl, but once the protective layer is peeled off of the Emboss 50, the banner lays absolutely flat and stays flat when it’s under the spring tension of the banner stand,” explains Fiore. “One nice characteristic of the Emboss 50 is that it’s a 5-mil vinyl, which is very flexible and not bulky. Plus, it has a very light crystal surface that doesn’t kill the pop of the print, yet it kills the reflection off of the graphic. I show this to my customers so they can see how beautiful the laminate is; that’s how much I like it.”

Thanks for the tips, Lou!