Alan Russell, manager of FastSigns – Airway in El Paso, produces a lot of day-to-day flat sign work, but the truth is that much of it you really wouldn’t characterize as “day-to-day.” In the examples pictured here, Russell and his crack staff had to find a custom solution that would stay within the customer’s budget.

“We’re located in a budget-conscious town, so we have to watch the bottom line and keep our re-cuts down,” says Russell. “A big part of that is picking the right print material. For our standard, all-purpose sign printing we mainly use LexJet Simple Adhesive Vinyl – Semi-Matte. We use it both on our Mimaki solvent and our UV-curable flatbed. It’s an economical vinyl that prints well. It also seems like our re-do’s have gone down in production because it’s a little thicker than most economy vinyls.”

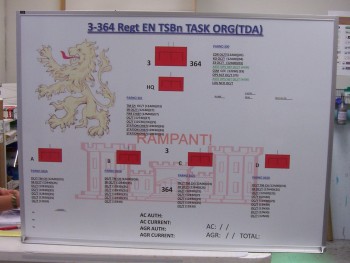

Dry Erase and Info Boards

FastSigns – Airway in El Paso serves the U.S. military base, Fort Bliss, and in doing so they’re asked to create fairly unusual pieces to support the base’s mission. Dry erase boards are a common request, which the shop fulfills using LexJet Simple Adhesive Vinyl for the background graphic, laminated with LexJet Dry Erasable Gloss Laminate (2 Mil).

“The solution has worked beautifully. The dry erase laminate doesn’t seem to be prone to the same issues as other dry erase laminates, such as having problems with certain marker colors,” explains Russell. “The vast majority of our customers will have us print their dry erase board graphic with the dry erase laminate, which we’ll mount to a piece of Dibond or similar material, and they end up with a relatively inexpensive dry erase board. We do a nice little rounded corner, put a couple of holes in it or put hardware on the back for them to hang it, or however they want it.”

Similarly, the FastSigns staff printed a change-of-command board with a wood grain texture to mimic the look of the old homemade boards made out of plywood. The old ones were, well, old, plus very heavy to move from place to place.

“I found a decent photograph of wood grain, printed the wood grain pattern for the background, and made a banner across the top out of Ultra Board with dimensional lettering and they were ecstatic. The fact that the vinyl provides some texture when printed on the flatbed is incredible. They were blown away because one guy can carry around this 4×8 piece,” says Russell.

Cut-Outs and Construction Barriers

Though FastSigns – Airway in El Paso does not have CNC equipment, they do a lot of die-cut signage with woodworking equipment. Russell says he likes LexJet Simple Adhesive Vinyl for these projects because it doesn’t tear when they cut it or peel it up.

Moreover, Russell says the vinyl works well with the flatbed printer. Though they could obviously print directly to the board (and they do), on flat sign projects that use larger pieces of board, Russell prefers to print to the vinyl. If there’s a misprint, it’s a lot easier and less expensive to re-print a piece of vinyl than it is a board.

“The heat doesn’t impact the vinyl, the ink bonds well with it, and the signs look great. The fact that it’s not super-shiny gives the pictures and logos they use a great finish: a real nice textured, almost painted look. It’s thick, so when someone bumps into it they won’t ruin it. It’s not a delicate vinyl, whereas other thinner vinyls aren’t as durable,” says Russell. “We have certain methods to be cost-effective, and this is one of them. We do not and cannot sell a cheap product. We have to be competitive on a square foot cost basis, but we can’t sell cheap stuff. We give them the product they need and they don’t have to spend a lot.”

For construction barricades and other similar projects, LexJet Simple Adhesive Vinyl is again the print material of choice. The project pictured here for a medical center was up for one day and consisted of about 14 panels.

Though it was a one-day event, the medical center used the panels for other events. “They used those panels for several years, they took a beating and they still look great,” says Russell.