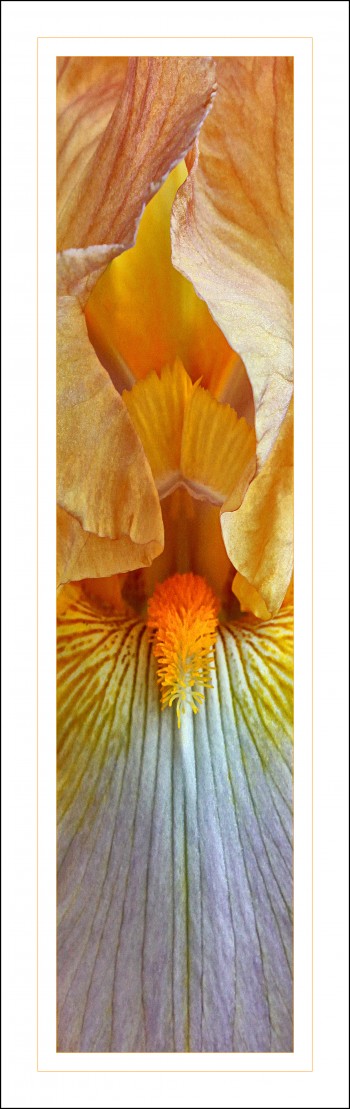

Before we get into the physical stretching and wrapping of canvas, this seems a good spot to discuss ways in which you can prepare the file before printing so that it’s ready to be rendered as a gallery or museum wrap. A gallery wrap, by the way, is where the image continues to bleed onto and over the edges. A museum wrap substitutes a solid border along the edges.

The trick is getting this right before you print. Fortunately, there are quite a few options…

Photoshop actions: Typically, the Clone tool is the primary tool used to create a mirrored border. You can do this manually in Photoshop and then record your actions.

Canon Layout Plug-In: If you have a Canon iPF inkjet printer, the Layout Plug-in software features a tool that automates the process.

OnOne Software, Perfect Resize 8: Formerly known as Genuine Fractals, with Perfect Resize you can create selective, mirror, museum-wrap and other types of wrap borders.

Qimage Ultimate: This imaging software tool offers a number of ways to work with print borders. Click here to see how it’s done.

Alien Skin Software: Alien Skin’s Blow Up software comes with a free Photoshop Gallery Wrap Panel to make a solid border, reflected edges or reflected edges with a fade.

Typically, there are three ways a canvas print can be stretched: by hand, with stretcher bars and strainers; using canvas stretching machines that provide a range of automation, like the Tensador II and the more automated Canvas Master machines by GAPP Engineering; or using a do-it-yourself stretcher bar system.

Typically, there are three ways a canvas print can be stretched: by hand, with stretcher bars and strainers; using canvas stretching machines that provide a range of automation, like the Tensador II and the more automated Canvas Master machines by GAPP Engineering; or using a do-it-yourself stretcher bar system.

Stretching canvas by hand can be very involved and time-consuming, but the raw materials needed are less expensive. For detailed step-by-step instructions by master printer, photographer and craftsman Ralph Cooksey-Talbot on creating your own stretcher bars and canvas frames, including the tools and materials necessary, click here.

While much more efficient for production, acquiring equipment like the Tensador II or the Canvas Master requires an initial investment ranging from about $3,000 to $11,000. If your volume supports the equipment purchase, definitely investigate these machines.

Armando Garcia, director of operations for Soicher Marin, a high-volume fine art reproduction company is Sarasota, Fla., says, “We use the Tensador for just about everything up to 60 inches. When you compare it to doing it by hand, the machine always wins out. I can’t think of a situation where we wouldn’t use the machine, unless it was an original canvas.”

Garcia adds that it usually takes one of their operators about a day and half to learn how to use the machine to its full potential and cuts the time needed to do a canvas wrap by anywhere from 30-50 percent.

The Canvas Stretch Master is more automated, thus it’s more expensive. However, it also produces about twice as many canvas wraps per hour than the Tensador II and the Canvas Studio Master, about 60 per hour on the high side, with less labor. To find out more about the setup and operation of the Studio Canvas Master and the Canvas Stretch Master, click to the videos below:

Studio Canvas Master Demonstration

Canvas Stretch Master Demonstration

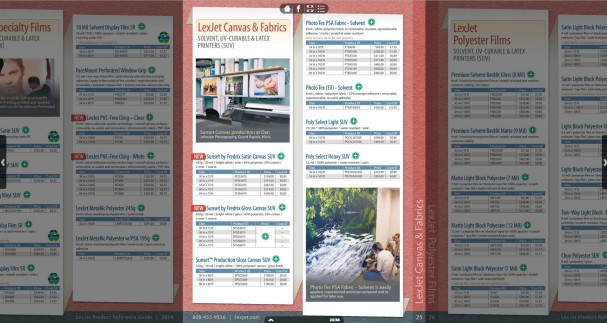

The third option is the use of a pre-made DIY stretcher bar kit, which include kits by Hahnemuhle and LexJet Sunset. This is a happy medium between stretching by hand and automating the process. Tara Materials also offers easy-to-assemble tongue-and-groove stretcher bars so you don’t have to buy the raw materials and cut them down to size.

While overall material costs are a little more than if you made the frames by hand, each canvas wrap will be faster than doing it by hand, but will obviously take longer than using a machine. For videos of the process, click here.

And, for more videos about printing, coating and stretching canvas, click here.

For the rest of this series, click on the following links:

Part 1: Materials, Finishes and Textures

Part 2: Printer Technologies for Canvas