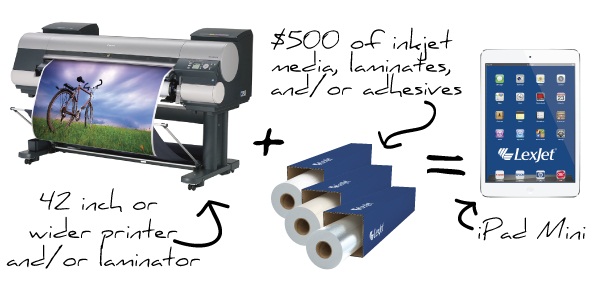

Starting today (Thursday, Nov. 15), LexJet is giving away an iPad Mini with every purchase of a 42″ or wider printer and/or laminator plus $500 of qualifying LexJet media (inkjet-printable media, laminates, adhesives and backers) for the next 30 days or while supplies last, so act quickly to make sure you get your free iPad Mini before we run out.

Go to lexjet.com/FreeiPadMini to see how much time you have left to take advantage of this special promotion for a free iPad Mini. Then, contact a LexJet customer specialist by phone at 800-453-9538 to cash in on this offer (the promotion can only be redeemed by calling in for it and is not available online).

Qualifying printers at LexJet include, but are not limited to: Canon’s iPF8400S 44-inch printer and iPF9400S 60-inch production printer; Epson’s SureColor S30670 low-solvent production printer and Stylus Pro 11880 64-inch photo printer, and; HP’s L26500 61-inch and L28500 104-inch production latex printers, Z3200 44-inch photo printer and Z6200 42-inch and 60-inch photo printers.

Qualifying laminators at LexJet include, but are not limited to: GBC’s 2080WFt 79-inch cold, hot laminator, Seal’s 44 Ultra Plus 44-inch cold, hot laminator, Daige’s Solo 55-inch cold laminator, and D&K’s Expression 42 Plus cold, hot laminator. For all the qualifying brands, equipment and media/laminates, go to lexjet.com/FreeiPadMini.

As an added bonus, all printer and laminator purchases come with free shipping and a $9.99 flat rate on all other orders from LexJet’s nationwide network of distribution centers. Plus, you’ll get free and unlimited product and technical phone support from your customer specialist.

With additional bundled offers from LexJet, Section 179 tax incentives from the Federal government, and end-of-year rebates and specials from our printer manufacturer partners – Canon, Epson and HP – this iPad Mini Giveaway Countdown offer is the perfect head start into the Holiday season.

For more information and to take advantage of this offer, contact a LexJet customer specialist at 800-453-9538.