As noted here earlier at the LexJet Blog, Canon recently announced a new line of wide format inkjet printers, and with these new printers comes a time-saving piece of software called the imagePROGRAF Layout Plug-In.

As noted here earlier at the LexJet Blog, Canon recently announced a new line of wide format inkjet printers, and with these new printers comes a time-saving piece of software called the imagePROGRAF Layout Plug-In.

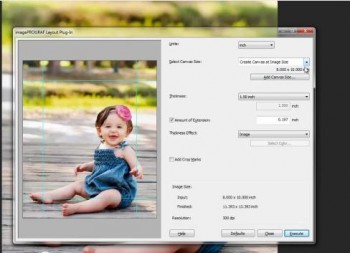

This software, exclusive to the new printers, allows users to bypass the usual steps in Photoshop of creating a mirror or solid color border around their canvas images for wrapping by automating the process after making a few selections.

Among other things, the Layout Plug-In allows you to enter:

- The desired print size

- The thickness of your stretcher bars

- The amount of canvas you want to stretch around the back of the bars for stapling

- Border effects like reflection (mirror), soft reflection (mirrored and blurred), and custom colors

After making your selections, the software generates the canvas and even automatically opens it in the imagePROGRAF Print Plug-In for Photoshop where you can print it.

In the video embedded below, learn about the various options that are available for your canvas prints and how to use the imagePROGRAF Layout Plug-In…