It’s the age-old dilemma: should I repair my old printer or just buy a new one? For Michael Thornton, administrative marketing manager at Bill Reed Distributing, Abilene, Texas, this particular dilemma presented itself when his old printer went down.

“As I was getting ready for the technician I picked up the phone and called Chris Piersoll, my LexJet rep. He said to hold up on the repair and first compare the cost difference between repair and replace, and the long-term productivity benefits of a new printer. We discovered that when you factor in the amount of down time we were experiencing, and the wear and tear it was a no-brainer to upgrade and pay the few hundred dollars difference for a new machine,” says Thornton. “The thing that concerned me most about repairing the one I have is the simple fact that it has a lot of miles on it. What’s the guarantee that something’s not going to happen a month from now? You know how this goes: you’re always in the middle of a big print project when it goes down. It was a much wiser investment to purchase a new machine because it is such a vital part of what we do; we can’t function without it. Marketing and sales pieces are critically important to supplement our sales. We love the reliability of the Canon printers, and at the price point LexJet is offering, why wouldn’t we buy a new one?”

Thornton upgraded to the Canon iPF8400S, which will provide the print shop with more speed and new color management and cost-tracking features. Moreover, with Piersoll’s help, Thornton was able to exchange the old ink cartridges he had in inventory.

“Chris was able to help us out with the ink we had for our old machine. I had a backup for every color sitting there, and that’s $1,700 that potentially I’d have to add to the cost of a new printer. That was one of the determining factors, and a lot of companies won’t work with you on swapping out ink cartridges,” explains Thornton. “So again, why wouldn’t you buy a new printer and guarantee yourself that you’ll have a great product and a new warranty. And with the Canon printer, minus changing out the printheads about once a year, there’s not much to do to keep them running.”

Ultimately, says Thornton, it’s all about consistency, productivity and efficiency. Thornton ran the old printer for 1,392 days after installation, printing about 180,000 square feet and more than 30,000 linear feet.

“While the old printer allowed me to go through sub-menus and look at how much ink was used per print, it’s very easy to factor your square footage cost with your media, but ink cost is not always the same because of color and saturation. What I’m really looking forward to with the new printer is the ability to be more detailed about tracking ink usage and actual costs; that’s invaluable, especially when you’re not having to dig for the information. It’s all about making things easier and working smarter,” says Thornton. “When you’re working with a number of convenience stores, and they all want their point of sale at the same time, you need to make sure the printer is running and it’s efficient. If it’s down, you’ve got a big problem. That’s what the big factor was for me. Look at how much we’re paying to fix the three-year-old machine, versus the cost for a new one. For all of us here, from the owner to the GM, the logical thing was to replace it; it’s been a great machine and let’s move on. Productivity is key.”

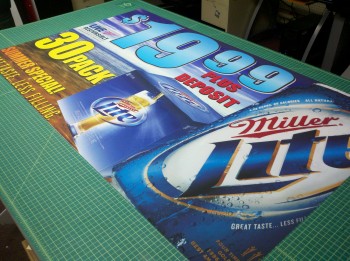

Though Bill Reed Distributing uses a wide variety of materials, from vinyl and Photo Tex to banner materials, Thornton adds that their standard print material is LexJet 8 Mil PolyGloss Banner. “The Canon prints such a beautiful graphic and when you put it on the glossy media it gives it a very classy look,” says Thornton.