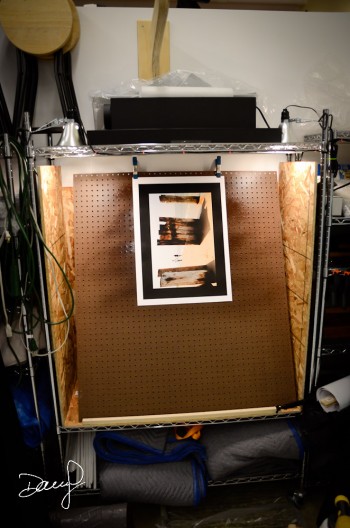

Printers and artists turn to Sunset Select Matte Canvas for projects as varied as unique, industrial-themed indoor art canvas wraps in Pennsylvania to weather-resistant fine-art photo banners in Idaho. The smooth texture, unsurpassed white point and crisp, rich photo production make it an easy choice for a multitude of projects and finishing treatments.

Versatile and durable, Sunset Select Matte Canvas was selected as one of 2010’s Hot Awards from Professional Photographer Magazine in the inkjet media category. And now, LexJet has released its next generation of the poly-cotton blend Sunset Select Matte Canvas.

The new Sunset Select Matte Canvas has a slight texture change and a higher Dmax, which means photos are even more detailed and vibrant. These improvements, however, haven’t altered the price, which remains the same for this 18 mil acid-free, pH neutral archival canvas.

Sunset Select Matte Canvas is available in standard roll widths from 17-inches to 60-inches in 40-foot rolls. It works with both dye and pigment inks and is compatible with current and legacy model printers from Canon, ColorSpan, Encad, Epson and Roland.

Call a LexJet print specialist at 800-453-9538 for more information and to try Sunset Select Matte Canvas for your next project.