For prints that are subjected to direct light, wear-and-tear or even graffiti, one of the most economical ways to protect them is with a coat or two of liquid coating. Water-based coatings, such as Sunset Gloss or Satin Coating as well as Marabu ClearShield and EnduraCoat options provide consistent, reliable and cost-effective print protection for everything from canvas wraps to wall murals to outdoor signage.

The benefit of using a liquid coating include abrasion resistance, extending the life of the graphic and making it easier to clean them, which is especially helpful for outdoor signage that falls victim to those graffiti artists. Coatings can also change the image’s finish — from gloss to matte, for example — which is one way to reduce the glare of a glossy print.

Ink Interaction & Coatings

While ink technology in inkjet printing has evolved significantly in recent years, even latex or solvent inks can use added protection from a liquid coating, especially for long-lasting or high-traffic prints (think: wallcoverings).

It’s especially helpful for prints displayed in direct sun, which need help against the UV light that can eventually wear away any ink. It’s important to remember, however, that ink-and-coating combinations can sometimes behave in an unpredictable way. Best to test compatibility before coating an entire job.

Water-based & UV Coatings

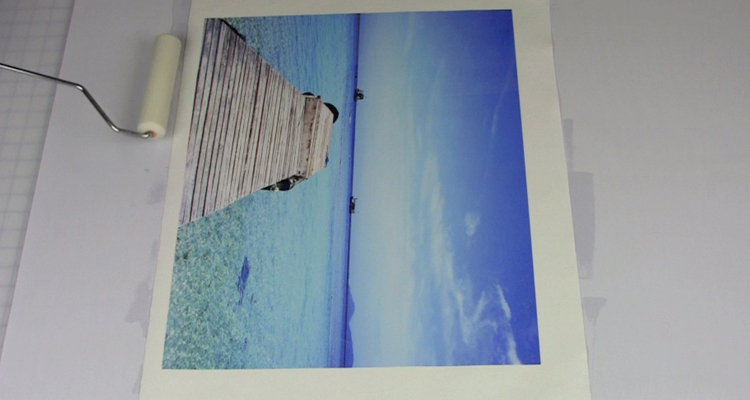

Water-based Coatings: For smaller jobs, a water-based coating is the way to go since they can be roller, mop or machine applied. These are great cost-effective alternatives to thermal or pressure-sensitive laminates. Since they are liquid, water-based coatings can conform to uneven surfaces when needed, which a laminate film cannot typically do.

These can also be machine-applied. Check out this video to see how easy it is to use the Marabu StarLam coating machine. Waterbased coatings range from $0.08 – $0.18 per square foot.

UV Coatings: Machine-applied UV coatings provide longer life at a lower cost, $0.04 – $0.10 per square foot, depending on the product. Our line of Mara Shield UV coatings are application-based, such as anti-graffiti, corrugated board and rigid or flexible substrates.

UV coatings dramatically extend the life of prints and intensify the color vibrancy of printed images. The MegaCoat XL 63 UV Coater can handle everything from films to boards that are 1-inch thick.

To learn more about coating, ink and substrate compatibility, check out our Print Protection page or call at LexJet coatings expert at 800-453-9538.

You May Also Be Interested In: