The name of the game in the beverage distribution business is branding and securing as much space as possible to advertise the brands at the point of sale, whether it’s in a beverage center, a bar or any other place that sells beer.

One of the hurdles to overcome when it comes to plastering an establishment’s walls with branding is the potential damage adhesive-backed graphics can do to it. One solution is Photo Tex from LexJet, a repositionable and removable printable fabric.

One of the hurdles to overcome when it comes to plastering an establishment’s walls with branding is the potential damage adhesive-backed graphics can do to it. One solution is Photo Tex from LexJet, a repositionable and removable printable fabric.

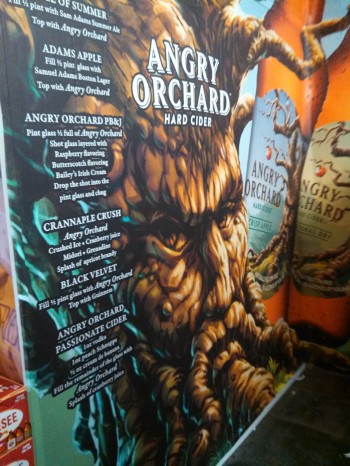

In the case pictured here, that’s what sold the job promoting Brown’s Brewing Company and Angry Orchard. The owner of the beverage center expanded his office, creating new walls that screamed out for branding.

Seeing an opportunity, DeCrescente Distributing proposed wall graphics. The owner hesitated, concerned about the potential damage to the wall.

“We proposed using Photo Tex, and explained that it would come off the wall easily without damaging it or leaving residue behind. That’s a big selling point for us,” says James Lane, DeCrescente graphic designer. “It also applies a lot easier than a typical adhesive-backed vinyl. It’s been up for a few weeks and we expect it will be up for a long time.”

As you can see from the photos, the design the DeCrescente graphics team came up with printed flawlessly on the print shop’s Epson GS6000 low-solvent printer, and provides an almost three-dimensional illusion of walking toward an actual brewery as you saunter down the aisle.

As you can see from the photos, the design the DeCrescente graphics team came up with printed flawlessly on the print shop’s Epson GS6000 low-solvent printer, and provides an almost three-dimensional illusion of walking toward an actual brewery as you saunter down the aisle.

The new wall mural also promotes the growler taps that protrude from the office wall. Lane says that was an important element the customer wanted to highlight.

“One of the reasons he extended his office was so he could have keg coolers in there with the taps coming out of the outside wall. People can come in and fill up their growlers with the beer specials of the day listed on the white board, which is what he has on tap,” adds Lane.